DTF RIP software is transforming printing for clothing brands by enabling direct fabric printing, eliminating intermediate steps, and optimizing digital artwork for accurate design replication and exceptional print consistency. It enhances production efficiency, reduces waste, and improves product quality while promoting sustainable practices. This game-changer optimizes print workflows, minimizes errors, speeds up turnaround times, and delivers high-quality results for custom items like hoodies and transfers.

“Discover how DTF RIP software is transforming print production. This cutting-edge technology offers more than just improved consistency; it’s a game-changer for print houses, enhancing every stage of the process. From understanding the core concepts behind DTF (Direct to Forme) RIP to exploring its key advantages in print consistency and workflow streamlining, this article demystifies this powerful tool. Embrace the future of printing with DTF RIP software.”

- Understanding DTF RIP Software: The Core Concepts

- Enhancing Print Consistency: Key Advantages

- Streamlining Workflow: Boosting Print Production Flow

Understanding DTF RIP Software: The Core Concepts

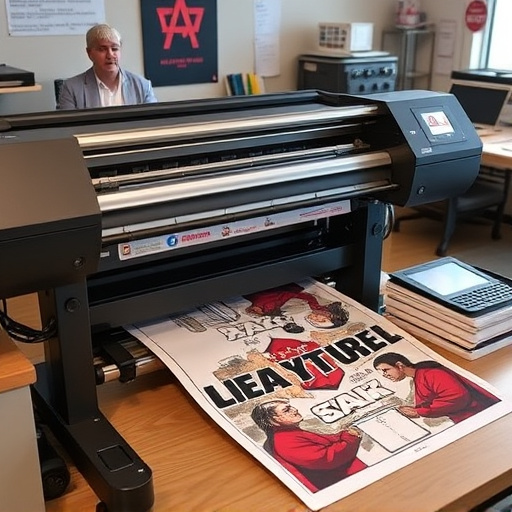

DTF RIP software stands as a game-changer in the printing industry, especially for clothing brands and custom dtf transfers. At its core, DTF (Direct to Fabric) technology enables efficient and precise printing directly onto various fabrics, eliminating the need for intermediate surfaces or plates. This revolutionary approach ensures that logos and designs are accurately replicated, offering unparalleled print consistency.

The software’s primary function is to rip, or prepare, digital artwork for direct printing. It translates complex design data into a format understood by printing machines, taking into account factors like color profiles, resolution, and fabric characteristics. By optimizing these parameters, DTF RIP software enhances the overall print flow, reducing waste and streamlining production processes. This not only benefits clothing brands by improving their product quality but also ensures a more sustainable and cost-effective printing experience.

Enhancing Print Consistency: Key Advantages

The implementation of DTF RIP software brings about significant improvements in print consistency, ensuring every printed item meets high-quality standards. This technology is a game-changer for businesses offering custom printing services, especially when it comes to popular items like DTF transfer designs on custom t shirts and hoodies. By optimizing the rip process, the software enhances color accuracy, allowing for vibrant and precise representations of intricate graphics.

One of the key advantages is the reduced risk of ink bleeding or smudging, which can mar the final product. The software ensures consistent ink distribution, resulting in crisp and well-defined prints. Moreover, it enables faster drying times, eliminating delays and enhancing overall productivity. These advantages contribute to a seamless printing experience, making it ideal for businesses aiming to deliver outstanding DTF printing results consistently.

Streamlining Workflow: Boosting Print Production Flow

DTF RIP software plays a pivotal role in streamlining print workflows, significantly enhancing productivity and efficiency in custom printing industries. By optimizing the process from design to production, this technology ensures a seamless experience for businesses offering personalized dtf printing for hoodies or custom dtf transfers. With its ability to manage complex layout designs, it simplifies the preparation of artwork for direct-to-film printers, resulting in faster turnaround times without compromising on quality.

This software’s versatility is particularly beneficial for print shops utilizing direct to film printers. It enables them to automate repetitive tasks, reduce human errors, and maintain a consistent output flow. Consequently, businesses can meet the high demands of custom printing markets while delivering orders with precision and speed.

DTF RIP software is revolutionizing the print industry by offering enhanced consistency and streamlined workflows. By understanding its core concepts, leveraging key advantages like improved print quality and efficiency, and adopting it in production flows, printers can elevate their output to new levels. Incorporating DTF RIP Software into your arsenal is a strategic move that promises to boost productivity and customer satisfaction alike.