DTF RIP software is a revolutionary tool for printing professionals, enabling precise color management in direct-to-film transfers (DTF). By separating CMYK and white channels, it ensures accurate color reproduction on t-shirts and other media. Users can maintain complete control over design layout using custom gang sheets, resulting in high-quality prints with intricate details and vivid colors. Best practices involve understanding job requirements, correct channel setup, and merging separated channels for optimal printing outcomes, meeting professional standards.

Unleash the power of precise color control with DTF RIP Software, a game-changer in digital printing. This article guides you through the intricacies of this innovative tool, revealing how it skillfully separates CMYK and white channels for optimal print results. From understanding its role in color management to exploring the step-by-step process and reaping benefits, gain insights into effective channel separation techniques using DTF RIP Software.

- Understanding DTF RIP Software and Its Role in Color Management

- The Process of Separating CMYK and White Channels Using DTF RIP

- Benefits and Best Practices for Effective Channel Separation with DTF RIP Software

Understanding DTF RIP Software and Its Role in Color Management

DTF RIP software plays a pivotal role in the world of color management, especially when it comes to direct-to-film transfers (DTF) and printing vibrant designs on materials like t-shirts. This innovative tool acts as an intermediary between design software and printing presses, ensuring precise and consistent color reproduction across various media. By separating CMYK channels from white channels, DTF RIP software enables printers to achieve a higher level of accuracy in their output, resulting in dtf printed shirts that accurately represent the original design intent.

In essence, the software translates digital designs into language that printing machines understand, accounting for factors like ink density, paper type, and environmental conditions. This meticulous process is crucial for maintaining color consistency, particularly when dealing with complex vibrant designs. By efficiently managing color profiles and settings, DTF RIP software ensures that what you see on-screen matches the final printed product, making it an indispensable tool for professionals in the printing industry.

The Process of Separating CMYK and White Channels Using DTF RIP

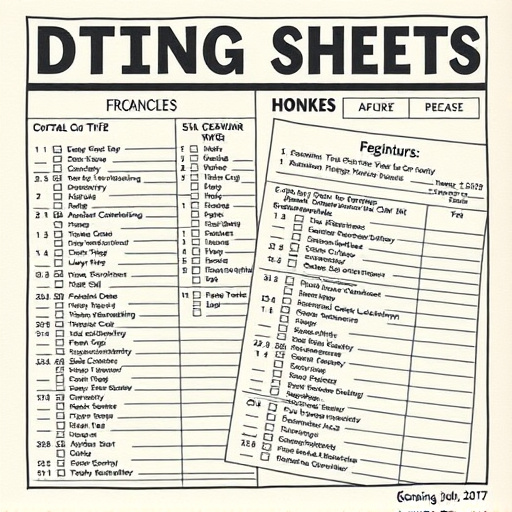

The process of separating CMYK and white channels using DTF RIP Software is a precise art that ensures optimal printing quality for dtf logo transfers. It begins with uploading your own gang sheet, allowing for complete control over the design layout. This digital tool interprets the design data, meticulously breaking down the image into its constituent color components: cyan, magenta, yellow, and key (black). By separating these channels, the software prepares the design for printing on specific transfer films, like dtf transfer film, which enables precise color reproduction and crisp details.

This separation is crucial as it allows print professionals to manage each channel independently during the printing process. The CMYK channels dictate the vibrant colors, while the white channel ensures the correct placement of white elements, preventing unwanted color bleeding or inconsistencies. This meticulous approach, facilitated by DTF RIP Software, results in high-quality dtf logo transfers, showcasing intricate details and vivid colors that bring designs to life on various materials.

Benefits and Best Practices for Effective Channel Separation with DTF RIP Software

Using DTF RIP Software for channel separation offers significant advantages when preparing print files, especially for complex CMYK and white channel arrangements. This technology streamlines the process, enabling precise isolation of color and white channels, which is crucial for high-quality printing. By employing DTF (Digital Transfer Format) RIP software, users can ensure that each channel is optimized for optimal ink distribution and final output.

Best practices involve understanding the specific requirements of your print job, whether it’s for dtf bulk orders or custom dtf gang sheets. Follow detailed application instructions to set up the channels correctly within the software. This meticulous approach guarantees that when the separated channels are merged during the printing process, the result is a vibrant, accurate reproduction without color shifts or white channel contamination. Such precise control is particularly valuable for intricate designs and ensures the final product meets professional standards.

DTF RIP Software is a powerful tool that simplifies complex color management processes, particularly in separating CMYK and white channels. By understanding its functionality and implementing best practices, printers can achieve superior print quality, ensure accurate color reproduction, and streamline their workflow. This innovative software is a game-changer for the printing industry, offering precise control over channel separation, which ultimately enhances the overall print experience.