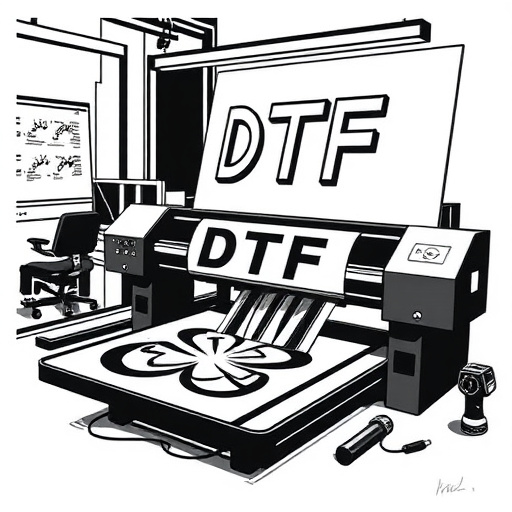

Adjusting print density and saturation in DTF RIP software is crucial for optimizing final prints. Density controls ink deposit, affecting opacity and color depth, while saturation determines color vibrancy. Balancing these settings prevents detail loss and ensures proper drying, resulting in long-lasting, high-quality prints. Starting with industry standards and adjusting based on visual feedback leads to a "sweet spot" that enhances appeal without obscuring details. For custom DTF transfers and gang sheets, optimizing saturation levels improves color accuracy and visual appeal, catering to diverse design requirements.

In the world of digital printing, achieving exceptional quality starts with understanding key settings in DTF RIP software. This article delves into two essential parameters: print density and image saturation. By exploring these, you’ll gain control over your prints, ensuring vibrant colors and precise details. Learn effective techniques for adjusting print density and discover strategies to enhance image saturation for optimal results, making your DTF RIP software a true game-changer.

- Understanding Print Density and Saturation in DTF RIP Software

- Adjusting Print Density: Techniques and Best Practices

- Enhancing Image Saturation for Optimal Print Quality

Understanding Print Density and Saturation in DTF RIP Software

Print density and saturation are crucial parameters in DTF RIP software that allow users to fine-tune the final printed results. Density refers to the amount of ink deposited on the substrate, impacting the image’s opacity and richness. Higher density means more ink, resulting in deeper colors and increased print quality, especially for intricate designs. On the other hand, saturation determines the vibrancy of colors, with higher saturation levels producing more vivid and intense shades.

Understanding these settings is essential for achieving precise prints, particularly when dealing with detailed DTF (Direct-To-Film) designs. The dtf curing process benefits from optimized density and saturation as it ensures the inks properly dry and cure on the substrate, leading to long-lasting, high-quality prints. Additionally, adhering to specific dtf design requirements, such as those related to color profiles and resolution, can further enhance the overall printing experience, making it a seamless process for both beginners and professionals alike when using DTF RIP software.

Adjusting Print Density: Techniques and Best Practices

Adjusting print density is a fine art when working with DTF (Direct to File) RIP software. It involves manipulating the amount of ink deposited on the substrate during the printing process, directly impacting the final print quality. Techniques include using advanced settings within the RIP software, such as varying dot size and screen frequency, to achieve desired contrast levels and depth. Best practices dictate starting with industry-standard settings for your specific medium and gradually tweaking values based on visual feedback.

For optimal DTF file preparation, it’s crucial to understand that higher print density doesn’t always equate to better quality. In fact, excessive density can lead to oversaturation and a loss of detail in fine lines or subtle color transitions. Conversely, too low a density might result in an image that lacks punch and clarity. Therefore, for high-quality DTF transfers, find the sweet spot where print density enhances the visual appeal without obscuring intricate details, ensuring your final output meets professional standards.

Enhancing Image Saturation for Optimal Print Quality

In DTF RIP software, optimizing image saturation is a key step to ensure top-tier print quality. By adjusting saturation levels, users can achieve vibrant and accurate colors in their final prints, which is particularly crucial for custom dtf transfers and gang sheets. Enhancing saturation during the digital stage directly impacts the visual appeal of the printed material, making it essential for professionals and enthusiasts alike involved in the dtf printing process.

To get the best results, consider playing with saturation settings based on your desired outcome. Increasing saturation can bring out richer hues and deeper blacks, while decreasing it can soften colors, providing a more subtle and natural look. This fine-tuning allows users to tailor their prints’ appearance, catering to diverse design needs for custom dtf transfers or the intricate layouts of gang sheets.

Customizing print density and image saturation within DTF RIP software empowers users to achieve exceptional print quality. By understanding the interplay between these settings, you can optimize your prints for various media and applications. Whether enhancing vibrant colors or refining subtle details, mastering these techniques ensures that your final outputs not only meet but exceed expectations. Incorporating best practices into your workflow ensures precision and efficiency in your printing endeavors using DTF RIP Software.