DTF RIP software is a crucial tool for digital textile printing, ensuring accurate color reproduction and consistent vibrancy across various materials. It bridges the gap between designer intent and final print, streamlining the process with real-time control and seamless integration. Indispensable for high-quality, on-demand printing in the textile industry, DTF RIP software is vital for cold peel DTF transfers and heat press techniques, enabling precise rendering of complex designs with vibrant colors on diverse fabrics.

“Unleash the power of precise printing with DTF RIP Software, a game-changer in color management and layout design. This article delves into the intricacies of this cutting-edge technology, exploring its pivotal role in controlling color interpretation for unparalleled output.

From understanding the fundamentals of DTF RIP software to its exceptional benefits, we’ll guide you through the process. We’ll showcase its versatility in handling complex layouts, highlight key tools, and present real-world case studies. Furthermore, we’ll uncover the secrets to consistent print quality and effective troubleshooting, ensuring your printing experience is seamless.”

- Understanding DTF RIP Software: Its Role in Color Management

- – What is DTF RIP software?

- – How it controls color interpretation and manipulation

Understanding DTF RIP Software: Its Role in Color Management

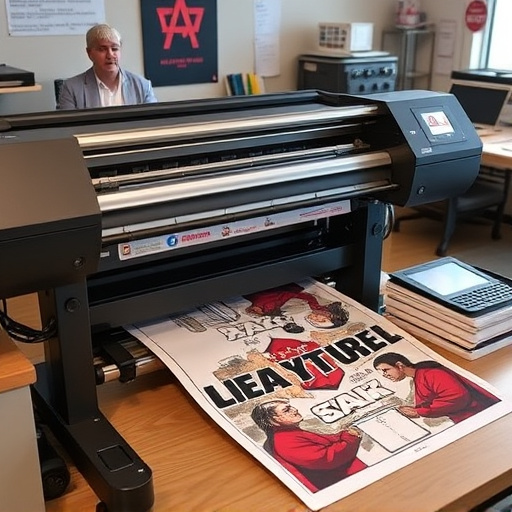

DTF RIP software plays a pivotal role in the digital textile printing industry by managing color accurately and efficiently. It acts as an intermediary between the designer’s intent and the final print outcome on fabric. This software is crucial for achieving consistent, vibrant colors across various materials, ensuring that designs translate from screen to garment seamlessly. By controlling color profiles, it enables printers to produce high-quality, on-demand prints tailored to specific textile applications like DTF transfer film or direct-to-garment (DTG) printing for apparel brands.

The software’s layout and design features allow users to preview and adjust color settings before sending jobs to the printer. This real-time control ensures that logos and graphics on dtf transfer film, for instance, maintain their vibrancy and detail. Moreover, DTF RIP software streamlines the print process, enabling clothing brands and other businesses to quickly adapt designs for different fabric types and achieve exceptional, consistent results.

– What is DTF RIP software?

DTF RIP software is a crucial component in the printing process, particularly for those utilizing cold peel DTF transfers and heat press techniques. It stands for Digital Transfer Format Render Interface, and it serves as the bridge between design software and printing hardware. This software controls and optimizes the color, layout, and final print output of DTF transfers, ensuring they are precisely rendered on various materials.

With DTF RIP software, users can effectively manage complex designs, including intricate details and vibrant colors, for their heat press projects. It enhances the overall printing experience by providing precise control over the final product’s quality, allowing for consistent and impressive results with the best DTF printer.

– How it controls color interpretation and manipulation

DTF RIP software plays a pivotal role in controlling and manipulating color interpretation during the printing process. It acts as an intermediary between the designer’s intent and the final printed output, ensuring precise color accuracy on various materials, especially when it comes to custom sheets for heat pressing designs onto garments. By managing color profiles, it calibrates the display settings of digital designs, translating them into corresponding physical colors on the print medium. This software enables users to adjust color channels, intensities, and saturations, offering a high degree of control over the final aesthetic.

For instance, in a direct to film printer or cold peel DTF transfers, the RIP software optimizes color representation, ensuring that vibrant hues and subtle shades are accurately replicated on the transfer film. This precision is crucial for achieving stunning, detailed designs when heat pressing onto garments. The software’s advanced color management system accounts for variations in printing substrates, ensuring consistent and high-quality results across different types of fabrics.

DTF RIP software stands as a pivotal tool in the realm of color management, offering precise control over color interpretation, layout, and final print output. By understanding its capabilities, professionals can optimize their printing processes, ensuring vibrant and accurate results. This software is not just a game changer for color-critical industries but also a testament to how advanced technology enhances the artistry of printing.